7 Smart Uses for Impact Gloves That You May Be Missing

When you think about impact work gloves, you probably think about protecting against blows to the hand. And while impact gloves are designed for exactly that type of injury, they also provide effective protection against other impact hazards too. Long a favorite on oil rigs and construction sites, today you can find impact gloves being used in a variety of jobs and industries.

Construction Demolition

Impact gloves are important for the work of constructing and assembling heavy duty items. But they’re also invaluable in the rough work of construction demolition and teardown. Pulling structures apart, handling concrete chunks and other abrasive materials, lifting and moving debris for disposal – these jobs and more are safer and more efficient with a glove that stands up to abrasion and provides more protection for the back of the hand. For the roughest jobs, look for impact work gloves with extra durable palm coatings and impact protection up to ANSI Impact Level 3.

Metal Fabrication

Much of the work in metal fabrication requires intense heat- and flame-resistant gloves. But some jobs like rolling, bending, forming, joining, hammering, and cutting metal may also benefit from impact protection and cut resistance. Some metal fabricators are choosing FR impact gloves to offer workers extra back-of-hand protection or even welders gloves with FR impact protection.

Handling Rebar

When it comes to rebar - whether you’re bending, shaping, sorting, or weaving it to pour concrete - it’s very easy for workers to bang their knuckles or cut their hands. Cut-resistant impact gloves are an ideal choice to protect against hard knocks as well as cuts and lacerations.

Moving Heavy Materials

Heavy materials are often unwieldy, resulting in increased crush and pinch hazards. One chemical distribution company we spoke to switched to impact gloves for workers moving large barrels of chemicals around their facility. The heavy barrel lids put workers at risk of catching their hands between the lid and the barrel, but TPR padding on the back of the glove helped to absorb impacts.

Assembly

Assembly often requires handling large, heavy materials. In the case of one aluminum assembly company, workers were building large appliance parts and handling oversized metal sheets, which often caused bruising and scrapes to the backs of their hands. Cut-resistant gloves took care of the scrapes but replacing them with cut-resistant impact gloves made bruises a thing of the past.

Machine Maintenance

Fixing machines often requires workers to place their hands in tight places with crush, pinch and impact hazards. Some safety managers are switching out the standard cut-resistant gloves typically used for this application and instead choosing breathable cut-resistant impact gloves or cut-resistant impact gloves with low-profile TPR. These gloves offer more protection to the back of the hand without trading the comfort and dexterity found in standard cut-resistant gloves.

Removing Excess Oil from Molds

Gloves featuring cut and heat resistance are often used for cleaning casts immediately after they come out of the mold. Some of the latest impact gloves now offer heat-resistance, cut-resistance, crush and pinch protection all in one glove, making them capable of protecting against all hazards involved in hammering excess edges from hardened molds.

General Maintenance and Other Lighter-Duty Jobs

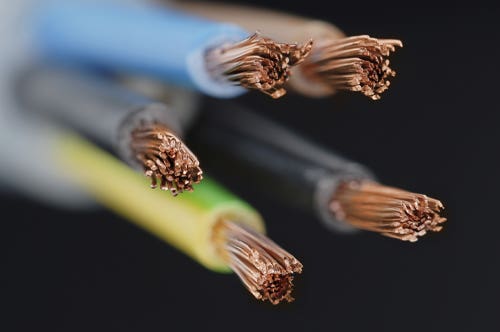

Even pulling electrical wire can involve cuts or bumps to the hand, but many lighter-duty jobs use gloves without impact protection. For jobs like general maintenance, I&E, light construction, assembly, or tool work, cut-resistant impact gloves with low-profile TPR are a perfect fit. If a job involves fine motor movement and a risk of scrapes, bumps, and bruises, workers will benefit from these gloves that have just enough protection without adding the bulk or stiffness that can cause hand fatigue.

See all the innovations in Impact Gloves

SHOW ME MY OPTIONS!