Coreless Cut Protection Just Got Better!

By John Heniff, Safety Writer, Magid

Magid® has taken coreless cut protection to the next level with DX+ Technology® (“DX Plus Technology”)! PPE made with coreless, cut-resistant fabric has been a popular choice for years as it’s lightweight, breathable, feels cool to the touch, and eliminates the skin irritation and contact dermatitis that many workers experience with traditional cut-resistant yarns. The downside has been that coreless fabrics were only available up to ANSI Cut Level A4.

GET THE BEST OF BOTH WORLDS IN CORELESS COMFORT & HIGH-LEVEL PROTECTION WITH DX+

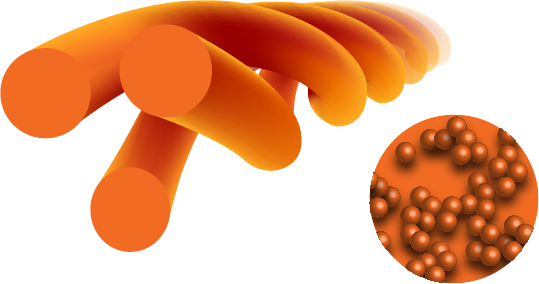

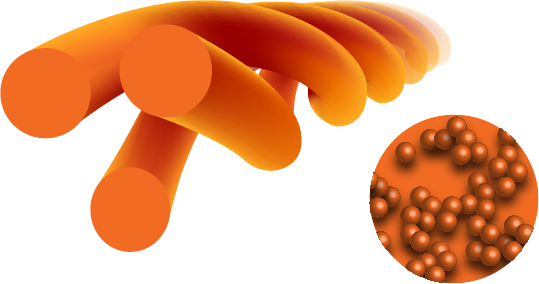

DX+ Coreless Technology is different than traditional cut-resistant materials because the core is replaced by yarn that’s infused with strength-enhancing microparticles. This microparticle technology achieves higher cut-resistance without becoming irritating or uncomfortable like gloves made with fiberglass, steel, or basalt inner cores that can fray or break over time and scratch workers’ skin contributing to contact dermatitis. And since these gloves don’t use a traditional core, they are 30% lighter than similar gloves of the same cut level. Best of all, DX+ has all the dexterity of other coreless fabrics but with even greater cut-resistance available in ANSI Cut Levels A5 and A6.

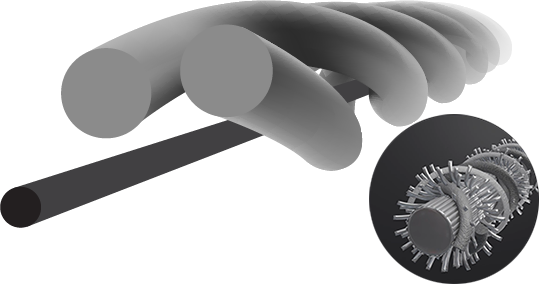

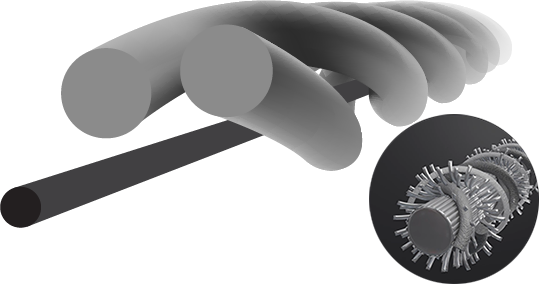

TRADITIONAL CUT-RESISTANT BLEND

Fiberglass, Steel, Basalt, or Graphene Core

-VS-

NEW CORELESS TECHNOLOGY

Strength Enhancing Microparticles

CUT-RESISTANCE YOUR WORKERS BELIEVE

Technological advances like this one can leave some workers wondering if such a thin, comfortable glove will really protect them from cut hazards on the job. But they can rest assured that these gloves deliver the same cut protection as a heavier model glove with the same cut level rating.

How do we know the gloves are up to the job? Magid puts cut-resistant PPE through a series of tests to ensure they can handle hazards on a typical jobsite and stay true to their ratings. These tests range from using a specially calibrated machine to drag a sharpened blade against a sample of fabric to filling a glove with closed-cell foam and running it against a common hazard like a sharp edge in the actual work environment. With these extra measures, you and your workers can be confident that a glove like DX+ can still hold up on the job even with its lightweight design.

WHERE CORELESS CUT RESISTANCE MAKES A DIFFERENCE

Industries that require gloves with high degrees of cut-protection can now have comfortable coreless protection through DX+ Technology. DX+ can protect against laceration hazards in jobs such as:

- Appliance manufacturing for sharp metal edges or handling metal parts

- Automotive manufacturing when working with or near sharp edges

- Construction when using sharp blades and other cutting tools

- Glass handling for broken panes or sharp edges

- HVAC operations for sharp blades and edges of HVAC units

- Machining when handling parts with sharp edges

- Metal fabrication for handling blanks and finished parts

- Paper production for cutters or other sharp objects

See the latest in coreless cut protection in action!