Search

-

Contact Us

Get help from our experts

877-237-9951

Office hours

8:00-4:30 PM Eastern

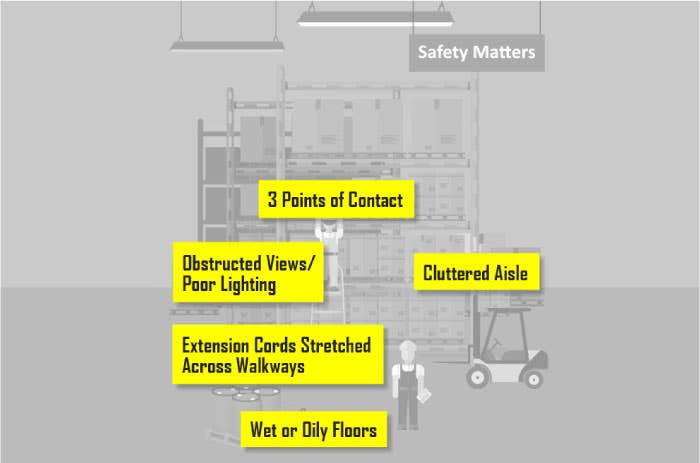

Take the Challenge: Find the Slip, Trip, and Fall Hazards

Slips, trips, and falls are the most common causes of workplace injuries. Are your eyes trained to spot these hazards? Click the reveal and read below for prevention tips on the slip, trip, and fall hazards we’ve hidden within this image. Then download a free presentation to train your workers.

Read More